Fortress designs and manufactures customised safety equipment, protecting people working in hazardous workplaces

Our interlocks control access into potentially hazardous areas, ensuring the area is safe before the employee can enter and keeping the employee safe while a task such as essential maintenance is being carried out.

We believe every employee working in a potentially dangerous environment around the world deserves the best possible protection, so we manufacture solutions to order UK, USA, Australia and China along with sales offices in the Netherlands and India. Our large global network of trusted safety experts ensure our customers’ and their individual needs are fully supported around the world.

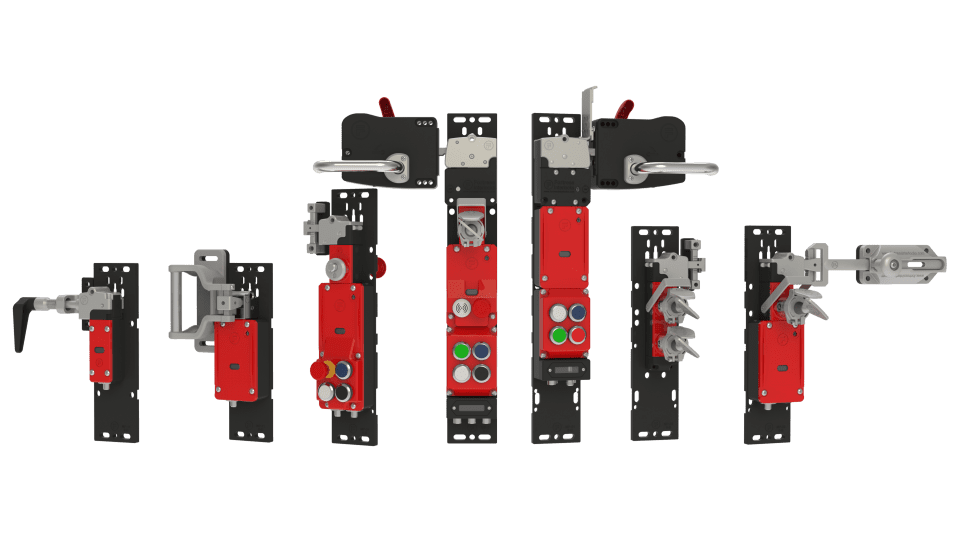

Heavy Duty Networked Interlocks and Control Pods

amGardpro is a highly versatile safety solution tailored to meet the specific needs of any application. Engineered, tested, and third-party certified for PLe/Cat. 4 or SIL 3 compliance, it’s ideal for industries prioritizing safety, such as manufacturing, automotive, F&B, and warehouse automation. This configurable system integrates pushbutton controls and trapped key options into a single, cost-effective unit. With network connectivity enabled through proNet, amGardpro seamlessly communicates with major industrial network protocols like EtherNet/IP, PROFINET, and EtherCAT, ensuring seamless integration into existing setups.

Mechanical Trapped Key Interlocks

mGard represents Fortress’s line of mechanical trapped key interlocks, third-party approved for use up to PLe/Cat. 4 or SIL 3 standards. Ideal for enforcing intricate safety sequences, especially in scenarios with multiple energy sources, mGard’s mechanical keys streamline installation and maintenance by reducing electrical wiring. Cost-effective and efficient, mGard benefits from Fortress’s comprehensive key and lock database, preventing unintentional key code duplication onsite.

Atom & FRNK – Compact RFID

Fortress presents Atom and FRNK, two robust solutions for safety switches and guard locking. Atom excels in handling dropped or misaligned guards and tight spaces with its innovative tongue design, suitable even for openings as small as 150mm radius. Its open head design simplifies maintenance by expelling dust and dirt, while the dual-channel safety channels and internal fault detection ensure enhanced safety and reliability. Meanwhile, FRNK offers reliable non-contact gate switching, providing peace of mind for machinery access with its compact size and versatile mounting options, aligning with ISO 14119 guidelines. Both Atom and FRNK come pre-wired with quick disconnects, requiring minimal mounting points for installation. With their durable designs, these solutions offer efficient and secure operation in various environments, ensuring the highest safety standards for your machinery.

Fluid Power Safety

Fluid power solutions from Fortress provide redundant means of operation, monitoring, and a unique cross link technology to guarantee no single component failure can affect safe isolation. Available for Category 4 (Cat. 4) and Performance Level e (PLe) applications. For run down times of a fluid system, zero pressure monitors are available to ensure safety is maintained.

- Positively driven dual mechanical contacts for reliable spool position monitoring when compared to alternative technology

- Crossed link exhausts to guarantee a path for pressure isolation

- Easily serviceable for minimal downtime

- Robust design for long lasting operation

Machine Controls & Safety

- Fully customisable and engravable (with text or symbols) buttons, lamps, and switches

- Easily integrate an emergency stop and external safe I/O

- Self-wired, hard-wired, or network connectable

- Robust, durable design utilizing metal componentry for long lasting operation

Safety Services

Customised safety services to fit your requirements

We have a team of machinery safety experts able to answer questions regarding international, European, and U.S. machinery safety standards. We have an array of free safety standard articles and webinars to help you navigate the complexity of the machinery safety standards.

We can provide tailored safety training related to U.S. and international machinery safety standards as well as standards related to specific applications. Contact us if you want to run company wide standards training or would like us to create tailored training for your applications.

Speak With a Dedicated TMMI Representative

TMMI has developed an extensive product offering through partnerships with industry leading manufacturers. With experience in the industry, count on us to meet your needs while improving your facility’s operation and efficiency.